Recently a Dutchtronix Oscilloscope clock module arrived by post, and it seems a really nice kit. Oscilloscope (or just "Scope") clocks have a fairly limited appeal, but the people they appeal to really, really like them. They are, in all seriousness, the pinnacle of geekness.

Q1: Who has a scope?

A1: A geek.

Q2: Who has a scope clock?

A2: A cool geek.

This article takes us through the first part of the build of the clock.

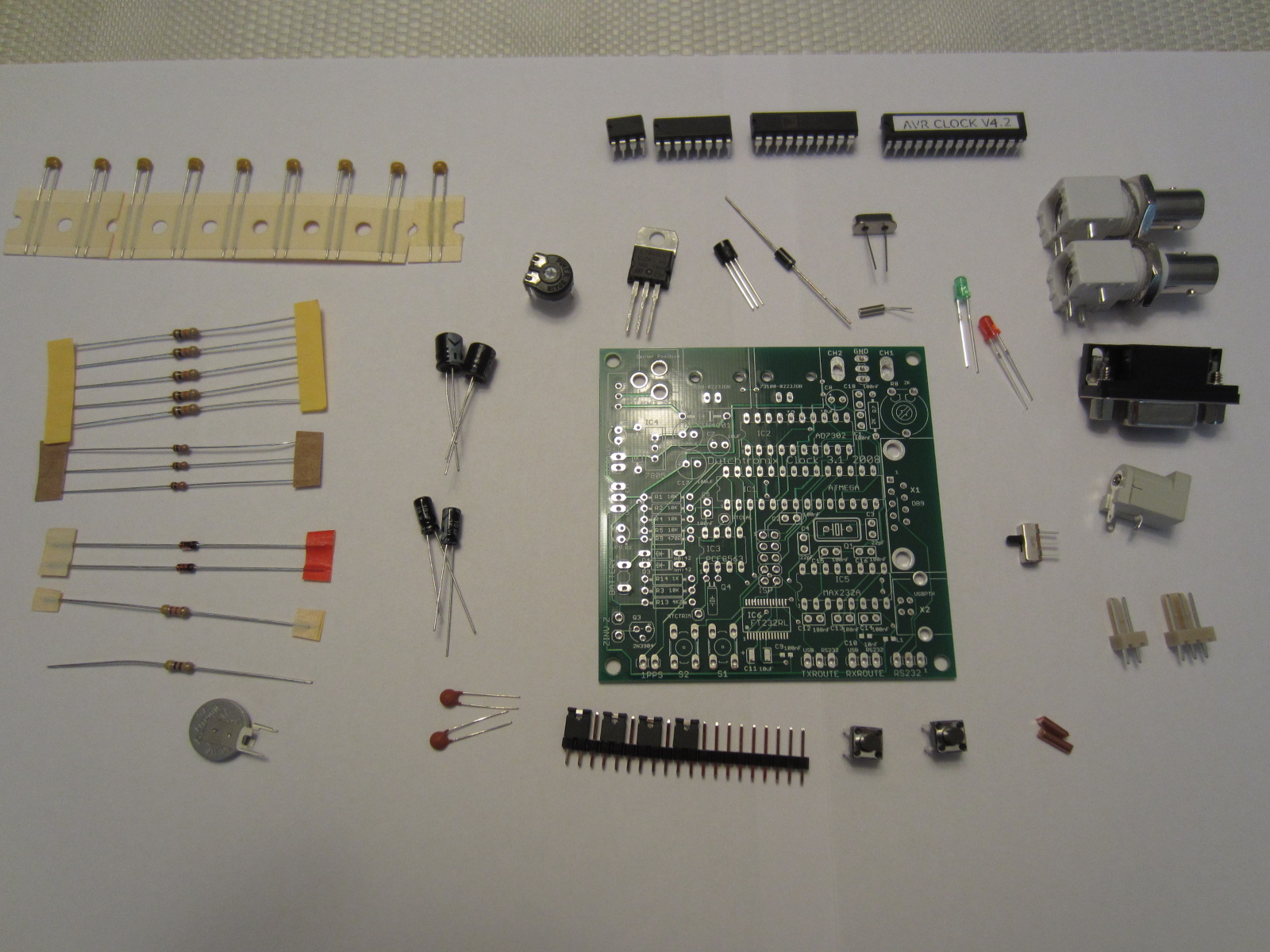

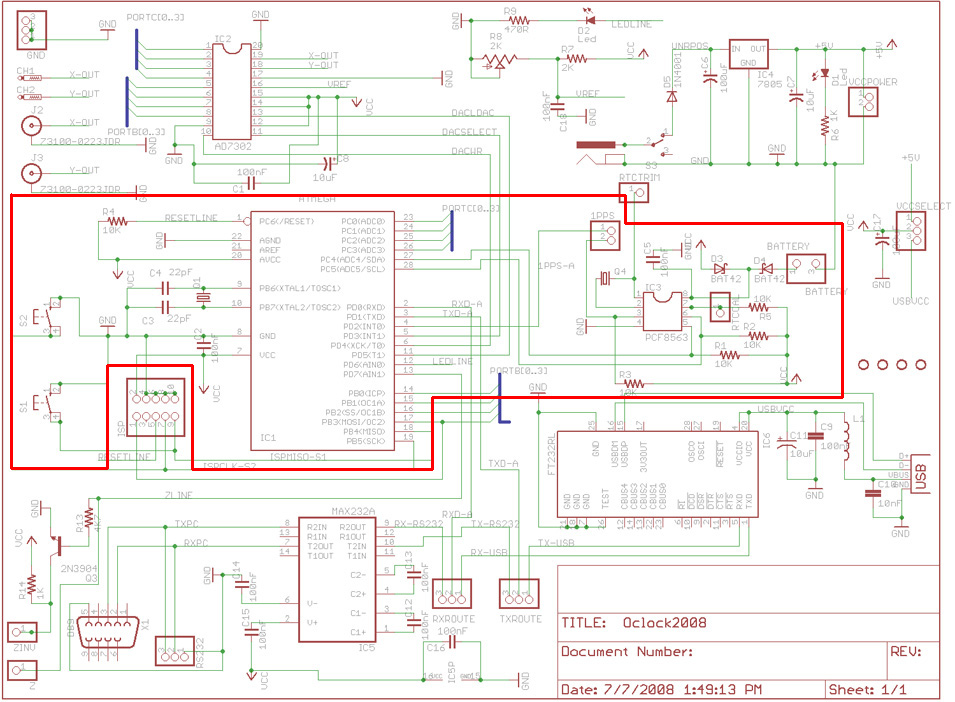

Before starting, it's worth looking at the information that is available on the Dutchtronix web site, and there is a LOT of it up there. This is a well documented kit, with all of the technical information that you might want. There are schematics, a parts list (even though the kit comes with all the parts you'll need), fairly detailed assembly instructions and even source code (but for a previous version, V4.0). The current software (V4.2) is only available as a pre-compiled binary file.

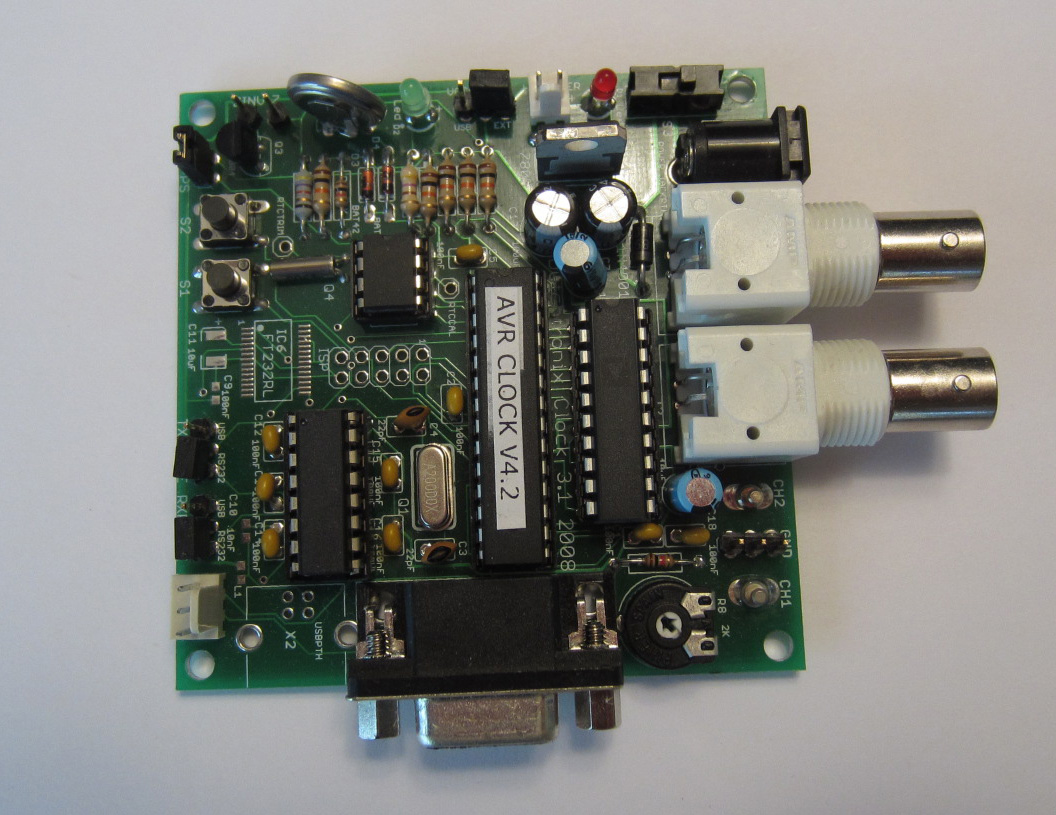

The circuit board itself looks well made and well laid out. I notice that this design is not new - it appears to date from 2008, as is written on the board. This is clearly a tried and tested design, but even though the circuit does not seem to have been updated recently, the design still seems to be thoroughly relevant and quite up to date; All of the components are currently and easily available, and are none look to be old or outdated generation components.

One possible trap for people who are inexperienced: There is a ground plane on the back of the board, and the "isolation" (the distance between the component pads and the ground plane) is very fine. If you are not that experienced with soldering, or are using a tip on your soldering iron that is too big, you risk making short circuits which are difficult to locate. The problem can come if you "dig" at a connection with the soldering iron, and remove some of the solder mask from around the pins (it's quite easily done if you are not careful, the solder mask is quite fragile). When you come to solder the pin, tiny whiskers of solder can form between the pin and the ground plane. It would be a valid modification to increase the width of the isolation, or at least make a note in the assembly instructions that make people aware of this risk. If you are careful, it will not be a problem, but you have to be careful.

Preparing for the Build

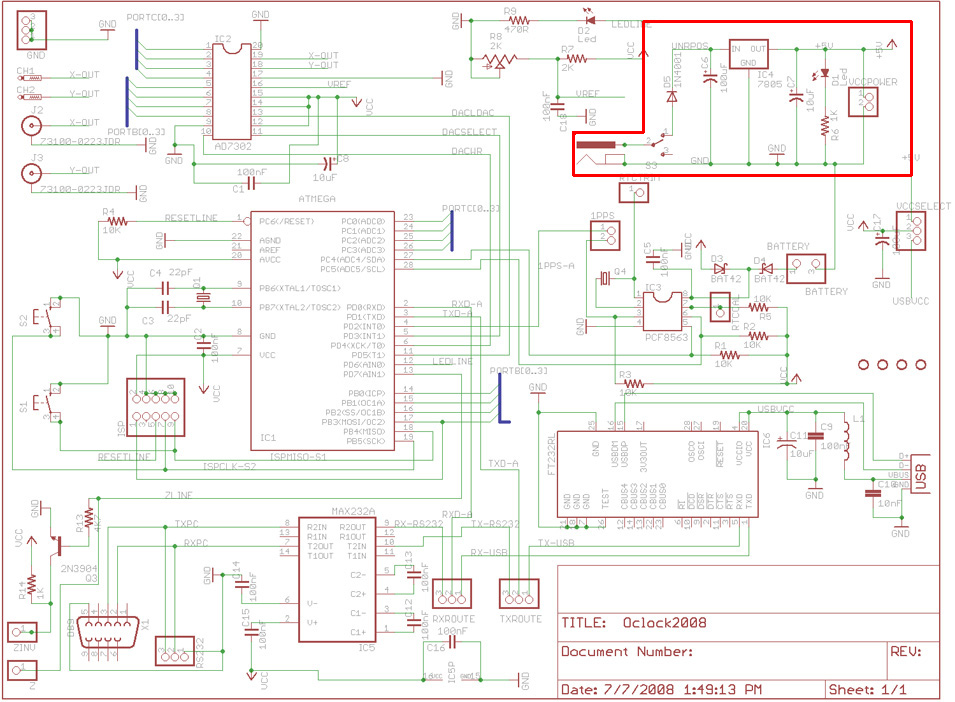

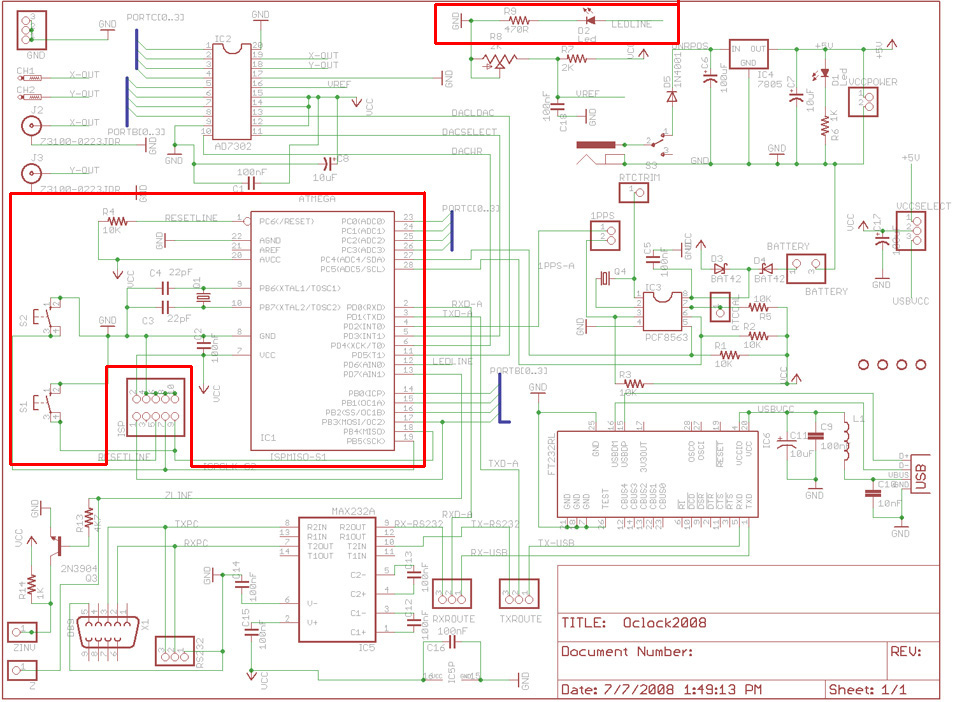

The first part of the build was therefore to get a feeling of what to build first from the schematics.

I decided to tackle the build in these stages:

The power supply

The controller

The RTC (Real Time Clock)

The reference voltage for the DACs (Digital to Analogue Coverters)

The DAC [Next episode]

The RS232 interface, and finally [Next episode]

The connectors and any sundries ("sundries" = bits that are still on the bench at the end = Things I forgot earlier, hmmmm) [Next episode]

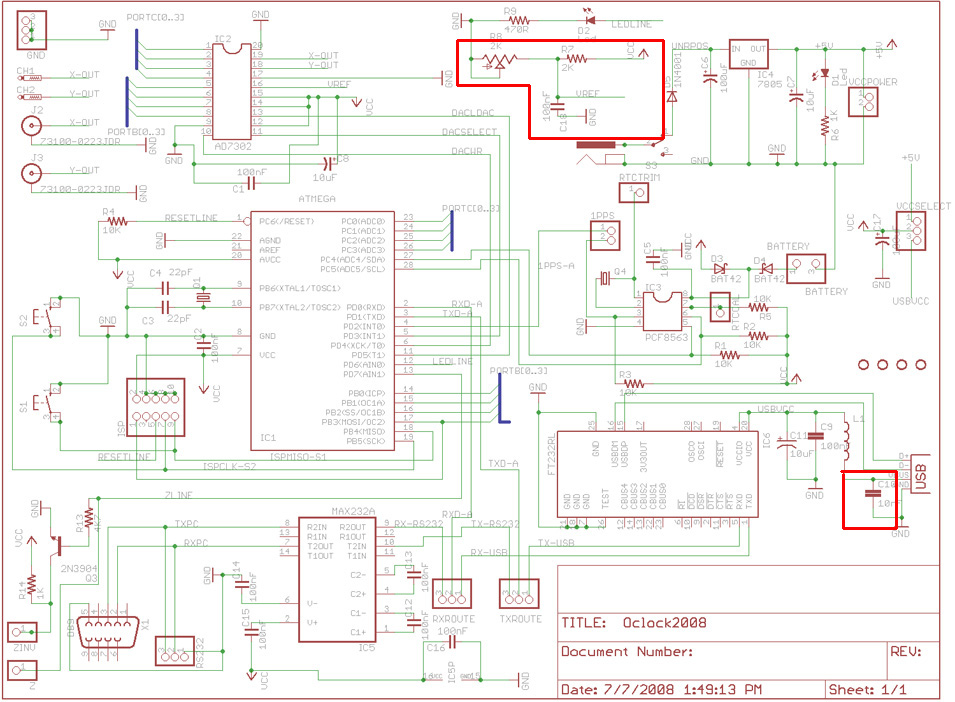

Building the Power Supply

I put in the components, and checked before powering it up that things were in the right orientation. Turning the power on, I was expecting the red LED to come on, but... nothing!

Going back the schematic, it became clear that the small "on/off" switch close to the barrel jack was missing. Adding that still didn't make the light come on. This time the "VCCSELECT" jumper was missing. This is used to select between external power and USB power.

Now it worked!

Putting the controller on the board

After installing the components, I was expecting the green LED to do something, but nothing happened at all. Pressing the buttons didn't change anything. I got out the oscillosope and probed the Atmega pins, to no avail. The controller had flatlined.

I wrote to Jan de Rie, and he answered quite quickly, given the time zone difference, but the answer wasn't that helpful. He said that the controller should start up when power is applied, but it didn't. I got out my home built Atmel programmer and read out the flash memory to check that something had been installed on the controller. It looked the same as the binary image available from the site. Moreover, the controller responded perfectly to the programmer, so there was clearly something else wrong.

One one of the FAQs there was a note that to put the controller into program mode, you need to hold down the switch S1 while powering on. I did this and the green LED started to flash, so it appeared that the controller circuit was just fine, but it was missing something to make the controller run.

The RTC circuit

Given that the controller was working (it flashed the green LED when you start the board in "flash" mode), I added the rest of the components in the extended red box, and then... IT WORKED! The Green LED flashed merrily!

The DAC reference voltage circuit

Next Episode

In the next part, we'll finish the build.

Video wrap-up